“Shotcrete” is a wet-method for the application of special monolithic

refractory materials.

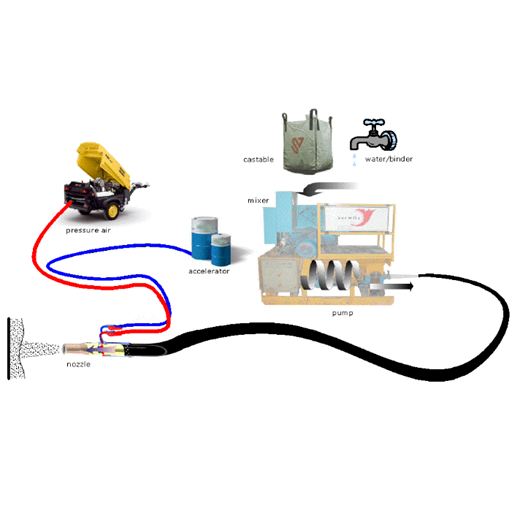

Premixed, pumpable refractory castables are conveyed to the place of

application with special high pressure pumps (approx. 250 bar) over

distances until 80 m and more.

The castables are “sprayed” with compressed air through a special nozzle.

Simultanously an accelerator is added and mixed in the nozzle, which

guarantees the bond and stability of the applicated castables at their

installation places.

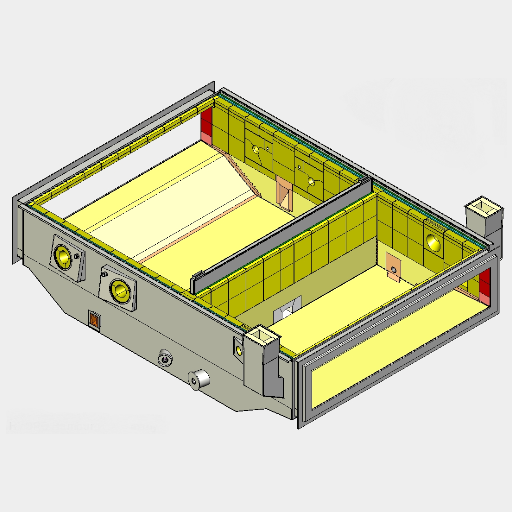

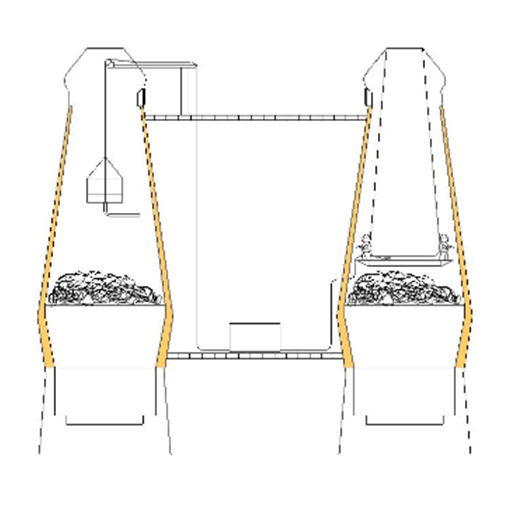

Comparing with conventional refractory casting castables, the “Shotcrete”

method achieves nearly the same physical values (density, strength).

For the application no complex formworks are necessary, which saves

precious time and costs.

A company in the business of Turnkey EPC Projects servicing a segmented value chain in Industrial and Infrastructural Sector Serving as a complete solution provider in the segment of Turnkey...

A company in the business of Turnkey EPC Projects servicing a segmented value chain in Industrial and Infrastructural Sector Serving as a complete solution provider in the segment of Turnkey...