Uniseven caters to the growing demand for refractories in the country emerging out of growth in the ferrous, non-ferrous, cement, petrochemicals and chemical industries. Our scope of supply of high-quality refractories includes:

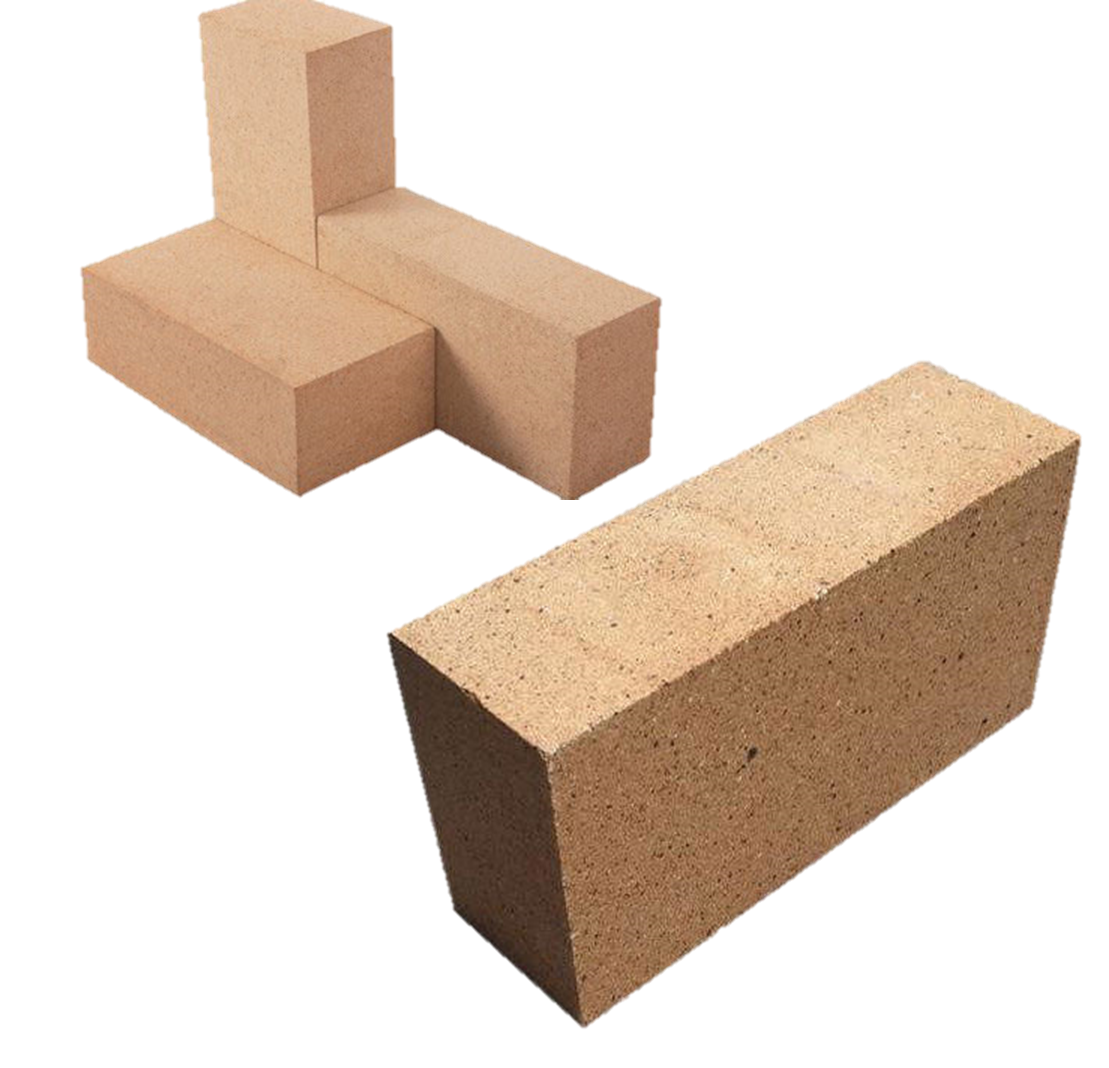

- Fire clay and high alumina refractories bricks (up to 90% alumina), including checkers and customized shapes for wide range of applications like coke ovens, steel ladles, re-heating furnaces, CC units, aluminium industry, cement industry and various non-ferrous sectors where the demand for quality and consistency is high

- Complete range of slide gate accessories comprising well blocks, nozzles, seating blocks and seating sleeves etc.

- Alumina-based abrasion resistant bricks as well as thermal spalling resistant bricks for critical applications in ferrous and non-ferrous industries

- Mullite refractories, sillimanite refractories and alumina chrome refractories for special applications

- The complete range of high purity (up to 95%) and medium purity castables for diverse applications

A company in the business of Turnkey EPC Projects servicing a segmented value chain in Industrial and Infrastructural Sector Serving as a complete solution provider in the segment of Turnkey...

A company in the business of Turnkey EPC Projects servicing a segmented value chain in Industrial and Infrastructural Sector Serving as a complete solution provider in the segment of Turnkey...